Background of the project:

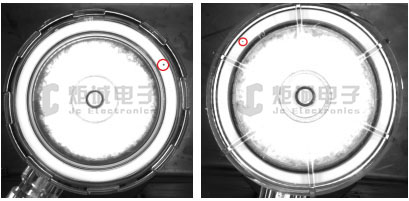

Dialysis tubes are generally used in clinical dialysis, direct contact with blood, so its standard of health is very high. However, due to the influence of the production art and the site environment, it is inevitable that occasional small dirty spots appear on the dialysis tube seal surface.

The traditional manual inspection methods have the following disadvantages:

1, detection efficiency is relatively low.

2, testing the standard of judgment is difficult to unify.

3, prone to eyestrain and judgment of the situation caused by miscarriage of justice.

The medical dialysis tube detection system adopts the visual detection technology based on the area array CCD, and can perform the high-speed detection function online in real time. The defective product is immediately alarmed and the control pipeline is shut down. After the operator removes the bad product, the product can be reset to continue production.

System Capabilities and Features

1, the use of independent design, can be freely installed in a variety of different types of production lines, without changing the original production line electrical procedures.

2, Compatible with different types of products with stiffener and non-stiffened surface on the surface, the detection area is automatically divided.

3, according to the material color difference automatically adapt to the detection threshold.

4, the test parameters set to open to the user, effectively shorten the commissioning time.

Common defects: