Background of the project:

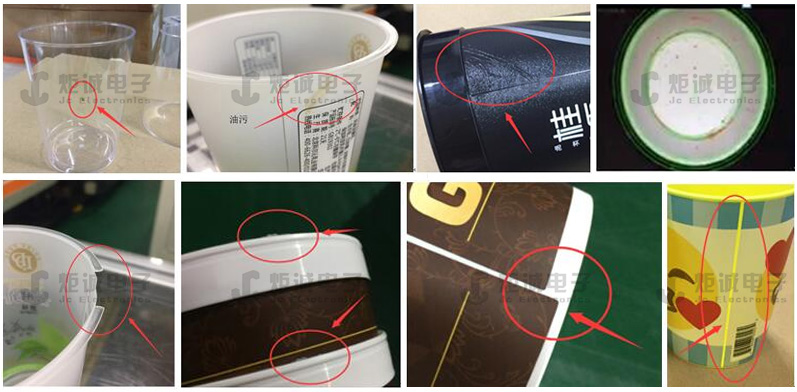

Cup products are very common in everyday life, and the hygiene requirements of such products must be very high because it directly affects the consumers' health. However, cup products in actual production process, due to various reasons, the cup surface will have dirt, oil, impurities, holes, notches, exposed, fried mouth, cracks and other defects, and part of the label or heat sealing label cup will appear Misaligned labels, missing stickers, inverted stickers, labels and other defects of dirty, seriously affecting the quality of products, unqualified product flow to the hands of consumers in the market, seriously affecting the consumer experience and corporate image.

Cup product testing system is a professional visual inspection system for cup product manufacturing line automation in the process of packaging, the cup products have the above defects can be detected in real-time under high-speed production conditions, online culling, to ensure product quality professional visual inspection system.

System Capabilities and Features

1, the use of independent design, can be freely installed in a variety of different types of production lines, without changing the original production line electrical procedures.

2, using multiple surface area camera at the same time detection, detection range can be set according to customer needs.

2, automatically capture the outer edge of the cup and the inner edge, automatically adjust the detection area.

3, the judgment of the dirty standard open parameters, users can customize the quality standards.

4, for the wrong labels and other design dimensions measurement function.

5, support defects point highlight instructions, and real-time high-speed remove bad products.

Common defects: